drawing process sheet metal These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels . In Starfield, help Louisa in deactivating junction boxes, tracing the power drain, and uncovering the culprits for ongoing brownouts in the Well.

0 · simple sheet metal drawings

1 · sheet metal forming drawing

2 · sheet metal diagram fabrication

3 · sheet metal deep drawing calculations

4 · sheet metal basic drawing

5 · metal spinning vs deep drawing

6 · metal sheet mechanical drawings

7 · deep drawing in sheet metal

In order to weld sheet metal or patch panels, you have to follow certain rules and use specific techniques. Proper technique will come with practice and experience. Also, it will ensure that you don’t get any warping of the materials you .

A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services.Sheet metal drawing is the process of shaping flat metal sheets into three .

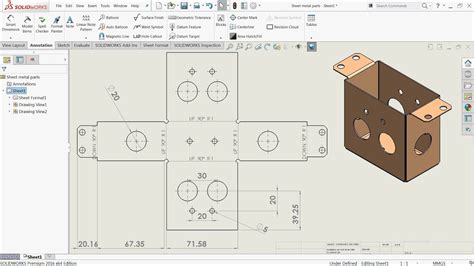

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, . These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels . Blanking: A flat sheet metal blank is cut from a larger sheet or coil to a precise size and shape using a blanking press. Lubrication: The blank is lubricated to reduce friction and .Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various .

However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should .

Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a .In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency. A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services.

Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

Blanking: A flat sheet metal blank is cut from a larger sheet or coil to a precise size and shape using a blanking press. Lubrication: The blank is lubricated to reduce friction and prevent tearing during the drawing process. 2. Tooling: Punch: A solid piece that pushes the blank into the die cavity.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking.

Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:

Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a cylindrical component with one side open.In sheet metal fabrication, having a solid grasp of CAD (Computer-Aided Design) drafting and modeling is essential for achieving top-tier product quality and operational efficiency.

simple sheet metal drawings

A complete guide to the world of sheet metal drawing, its processes, applications, benefits, and Prolean’s Sheet Metal Drawing Services. Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Blanking: A flat sheet metal blank is cut from a larger sheet or coil to a precise size and shape using a blanking press. Lubrication: The blank is lubricated to reduce friction and prevent tearing during the drawing process. 2. Tooling: Punch: A solid piece that pushes the blank into the die cavity.

Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. As mentioned, the punch and die setup is somewhat similar to a sheet metal cutting operation, such as punching or blanking. Sheet metal drawing is the process of shaping flat metal sheets into three-dimensional objects by stretching, bending, and forming them into desired shapes. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. However, regardless of the many factors involved, the most important element to a successful deep drawing operation is initiating metal flow. The following are key elements affecting metal flow, and each of them should be considered when designing, building, or troubleshooting deep drawing stamping dies:

Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. The deep-drawing process converts a sheet metal blank into a cylindrical component with one side open.

scame aluminium junction box

schaefer's electrical enclosures inc

Welding sheet metal is easy when you know the right techniques to apply. Refer to the tips on using sheet metal welding to improve your welding skills and make it work best for you. Of course, you can also leave it to the professionals.

drawing process sheet metal|metal sheet mechanical drawings